Aseptic preparations include injections directly injected into the body and non-gastrointestinal preparations directly used in wounds or mucosa. It is very important to ensure the quality and safety of aseptic preparations because of the special administration site of aseptic preparations. There are two aseptic processing for aseptic injections in pharmaceutical industry,terminal sterilization process and aseptic processing.

About Terminal Sterilization Process

Terminal sterilization process is the process to sterilize an injection product after embedding by moist heat sterillization. Generally speaking, the cost of terminal sterilization process is low, and the aseptic guarantee level is high. It is suitable for sterilization of large-volume injections.The glucose infusion, sodium chloride infusion, ringer lactate infusion, metronidazole infusion etc we supply is produced by this aseptic processing procedure.

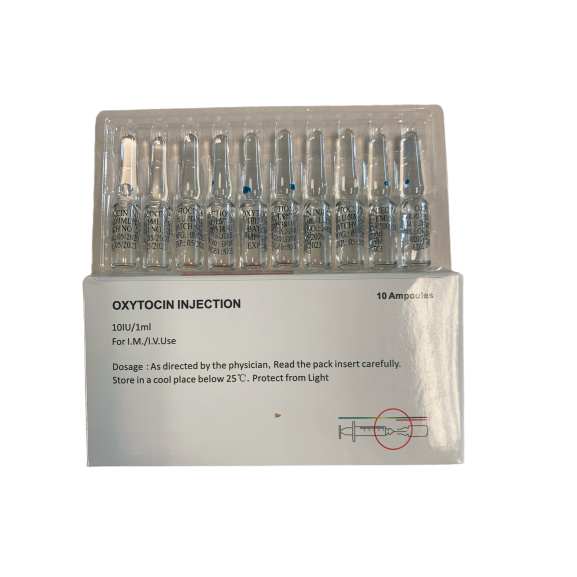

About Aseptic Processing

Aseptic processing, also known as non terminal sterilization process, is a processing technique ensures aseptic guarantee level by sterilization filtration or aseptic operation under sterile conditions. Aseptic production process is suitable for powder for injection products, such as ceftriaxone sodium for injection, Hydrocotisone Sodium Succinate for injection.

Principle of injection sterilization process

Sterilization is an important process ensures the quality and safety of injection preparations. In order to ensure aseptic guarantee level, it is necessary to follow the below principle of injection sterilization process.

Give priority to terminal sterilization process which has high aseptic guarantee level.

Choose non terminal sterilization process only while there is sufficient evidence to show that terminal sterilization process cannot be tolerated.